The performance of a Drone Ground Station looks solid in the lab. Then the sky changes. A light drizzle, a dusty breeze, a crowded RF arena - and control starts to slip. Screens lag. Links wobble. Batteries drain faster than planned. The crowd is watching, and your margin shrinks. Why does a station that works on the bench struggle outside? Is it the weather, the workflow, or the wireless noise? Today we pull back the curtain on the hidden failure points - and the fixes most teams overlook. Stay with us; the most costly weak link is the one you can't see yet.

Why Ground Stations Fail When The Weather Turns

Outdoor work punishes fragile systems. Heat drives radios and tablets into thermal throttling. Cold slows batteries and screens. Moisture creeps into connectors. Dust turns good contacts into intermittent headaches. Add RF clutter from Wi-Fi, 5G, production gear, and nearby events, and your control link can wobble at the worst moment. A Drone Ground Station that looks fine on a bench can struggle the moment wind, rain, and noise show up together.

There's also a human factor. Turnarounds between sorties are busy and stressful. Cables get moved, antennas slip out of alignment, and ad-hoc power banks sag. Every manual touch adds risk. When your process relies on perfect human timing, failure isn't an "if," it's a "when."

✅ Field pain points we see most often

• Midday overheating leads to throttled radios and laggy tablets

• Micro-rain or condensation shorts half-sealed connectors

• Stadium-level RF crowding cuts range and pierces telemetry

• Brownouts from improvised power cause random reboots

• Long reset cycles stack minutes into lost show time

The symptoms are familiar: command latency, broken telemetry, and forced aborts. If your Drone Ground Station falters when the weather shifts, you're probably seeing a blend of environmental ingress, RF interference, and manual workflow drag.

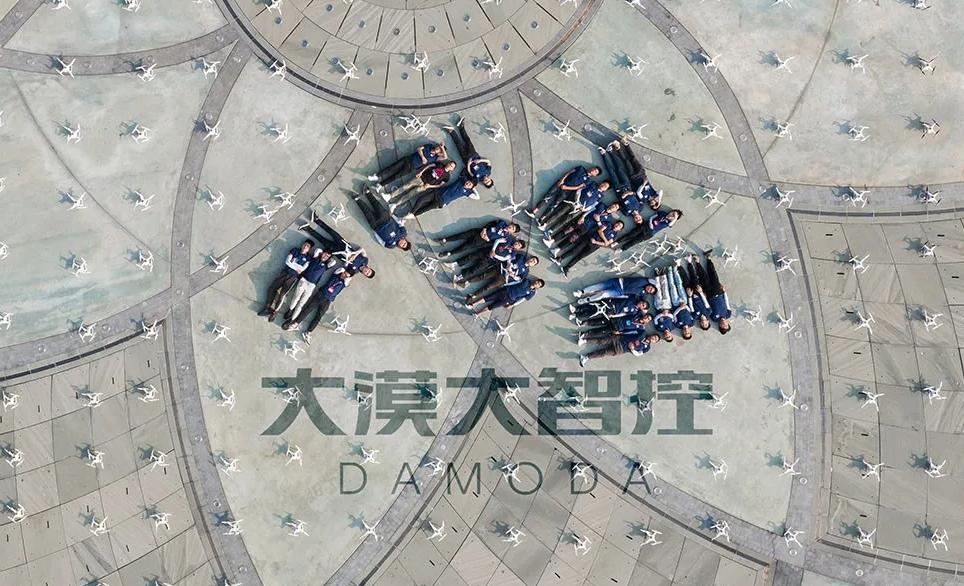

How DAMODA Builds For Real-World Harshness

We design our Light Show Drone V4 ecosystem - drones, charging nests, control software, and the Drone Ground Station - around three pillars: ruggedness, resilient links, and automation. The goal is simple: keep the show running when conditions refuse to cooperate.

1) Rugged Power, Resilient Links

Our hardware targets the envelope operators actually face: -20 °C to 50 °C operation, IP54 protection, and micro-rain tolerance referencing GB/T 28592-2012. Communications combine long-range control (up to 2 km line-of-sight) with diversified paths - 5G, Wi-Fi, and 2.4 G radio - so a single noisy band doesn't take you down. If a link degrades, the system aims to fail gracefully rather than suddenly.

Safety is layered. An automatic parachute can deploy at roughly 30 - 60 m if parameters are exceeded, protecting people and equipment. It's the backup you hope never to need, but it matters in public venues and close-quarters shows.

Automation That Shrinks Human Error

Most mission hiccups start on the ground. That's why our machine-nest fast charging eliminates the most failure-prone step - manual battery swapping. With one setup you can relay indefinitely through automatic charging, cutting re-launch intervals to about 40 - 60 minutes with no battery handling. Fewer touchpoints, fewer mistakes, calmer operators, and a Drone Ground Station that stays stable even under time pressure.

2) Precision, Scale, And Simplicity

Harsh environments aren't just about weather; they're tight sites, uneven terrain, and live audiences demanding perfect visuals. We pair millimeter-level positioning with upgraded RGBW lighting and real-time fill-point algorithms, so formations remain crisp even when the site forces compromises.

On the software side, we targeted the biggest bottleneck: scripting at scale. Our latest tools push launch/land script generation for thousand-drone clusters up to 10x faster, and overall production efficiency about 3x higher. More speed means more rehearsal, which translates into fewer surprises in the field. We also support 11 takeoff site types to match the reality of imperfect venues. And because skill transfer matters, we provide pre-sale and post-sale training so teams ramp quickly and safely.

Put together: ruggedized hardware + multi-path comms + automated power + faster scripting = a Drone Ground Station that stays steady when everything else gets loud.

What You Can Do Today To Stabilize Your Drone Ground Station

Before you buy anything new, fix fundamentals. We teach a few habits that deliver outsized gains in reliability, especially for outdoor shows and missions.

✅ Field-ready setup checklist

• Treat power as a miniature system: regulated sources for radios and tablets; avoid shared USB hubs

• Maintain antenna hygiene: correct gain for the venue, hard-locked orientation, clear line-of-sight paths

• Improve environmental sealing: IP-rated cases, drip loops on cables, spare desiccants for humid nights

• Run RF scans on site: pick the quietest channels, verify before doors open, keep a fallback profile

• Prioritize automation: enable auto-charge, scripted relaunch, and standardized checklists

Now stress-test your current kit. If weather is the villain, chase IP rating, thermal design, and sealed connectors. If turnarounds are chaotic, automate charging and trim manual steps. If link quality dips in crowds, diversify transport and pre-plan channel splits. Your Drone Ground Station should be an anchor, not another variable competing for attention.

Here's where the DAMODA Light Show Drone V4 ecosystem fits. We engineered it to hold steady in difficult conditions with IP54 protection, -20 °C to 50 °C operating range, ~2 km communications, automatic charging that removes battery-swap drama, and layered safety culminating in parachute rescue. In controlled runs, operators have reported reliability approaching nearly 99.999%, which is the level you need when there's a live audience, a tight schedule, and a forecast that can change within the hour.

- A Quick Word On Creative Output

Reliability is only half the story. A show still has to look great. Our RGBW lighting drives cleaner whites and richer colors for cinematic images, while real-time fill-point algorithms preserve the intended shapes even when wind or minor site changes push units around. Millimeter-level positioning keeps spacing tight, so photos and broadcast feeds look the way they were designed.

- Scale Without Extra Stress

Bigger shows usually mean exponentially more planning. We flipped that script. With our upgraded design software, thousand-drone projects don't need thousand-hour scripts. Generation is up to 10x faster, and production efficiency increases by about 3x, cutting the dead time that used to eat rehearsals. Less friction means more time to test, refine, and de-risk - exactly what outdoor work demands.

Call To Action: If you're ready to harden your Drone Ground Station and lower the stress of outdoor operations, talk to DAMODA. We can walk you through a fast assessment, show a live demo of our automated charging and control workflow, and recommend a training path for your team. Let's make your next show - or mission - your most reliable one yet.